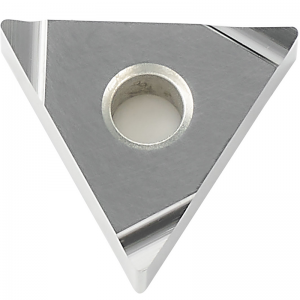

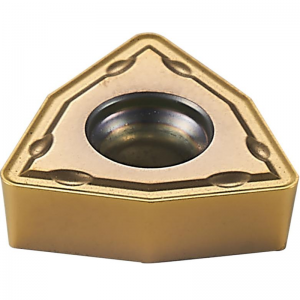

CNMG120404-MA Turning Insert

Short Description:

CNMG120404-MA, CNMG120408-MA, CNMG120412-MA are three common blade models for metal cutting. The following is a technical introduction and comparison of them: CNMG120404-MA Insert: This insert features precise tool geometry and edge parameters for consistent cutting performance. It adopts high-hardness blade material, which has good wear resistance and fracture strength. After special coating treatment, it can reduce cutting friction and heat generation, improve cutting efficiency and tool life. CNMG120404-MA is suitable for various fine cutting and high precision machining operations. CNMG120408-MA insert: This insert is designed with optimized tool geometry and edge parameters. It is made of high-quality carbide and can withstand greater cutting loads. After special coating treatment, it has lower cutting friction and heat accumulation, thereby reducing tool wear, improving cutting accuracy and surface quality. CNMG120408-MA is suitable for general cutting and rough machining. CNMG120412-MA insert: This insert has specially optimized tool geometry and edge parameters. It is made of high-hardness alloy material, which has excellent wear resistance and fracture resistance. After special coating treatment, it can reduce friction and heat accumulation during cutting, improve cutting efficiency and tool life. CNMG120412-MA is suitable for heavy cutting and high load processing. The common feature of all three inserts is that they are manufactured from high-quality materials and have excellent cutting performance and wear resistance. Their geometry and cutting edge parameters are precisely designed to make the cutting process more stable and efficient. At the same time, coating treatment technology can reduce cutting force and heat, prolong tool life, and improve cutting accuracy and surface quality. In terms of difference, CNMG120404-MA is suitable for fine cutting and high precision machining. CNMG120408-MA is suitable for general cutting and rough machining. CNMG120412-MA is suitable for heavy cutting and high load processing. Users can choose the most suitable blade model according to specific processing requirements to obtain the best cutting effect and processing quality. These inserts are widely used in manufacturing and process industries to improve productivity and product quality.